3D Line Confocal Sensor

Line scan confocal, one step to get the job done

Excellent dynamic detection·Simultaneous output of 3D and 2D images

1μm ultra-high repeatability

20μm absolute measurement accuracy

62 x 62mm super large field of view

Ultra-high-speed dynamic measurement

Output 2D/3D images simultaneously

Complete SDK and one-stop support

Product Description

- Hypersen HPS-LCF/X series 3D line spectrum confocal sensors break through the limitations of traditional detection methods and provide optical precision detection sensors with higher measurement accuracy and faster measurement speed for the Industry 4.0 era. For complex materials such as transparent glass film materials, lithium battery products, 3C electronic products, and semiconductor components, 3D inspection with sub-micron accuracy can be performed.

Coaxial measurement

Coaxial measurement

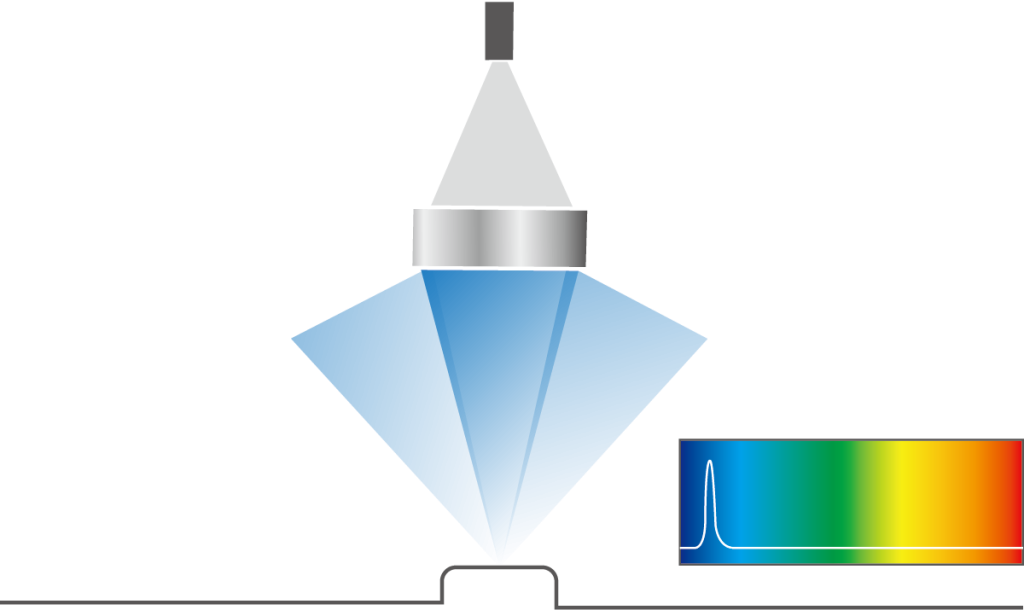

Principle Introduction

- Spectral confocal measurement uses a special lens to extend the focus halo range of light of different colors, forming special amplified chromatic aberration, so that light corresponding to a precise wavelength will be focused on the measured object according to the distance from the measured object to the lens. By measuring the wavelength of the reflected light, the precise distance from the measured object to the lens can be obtained.

- The intensity of the reflected light does not affect the measurement results. This means that no matter how much reflected light is reflected from the object being measured, the measured distance result may not change. Because the intensity of reflected light only depends on the degree of reflection of the reflecting object. Therefore, using Hyperson’s 3D line spectrum confocal sensor, normal and reliable measurement can be performed even if the measured object is a strong light-absorbing material, such as black rubber; or a transparent material, such as glass or liquid.

Product Advantages

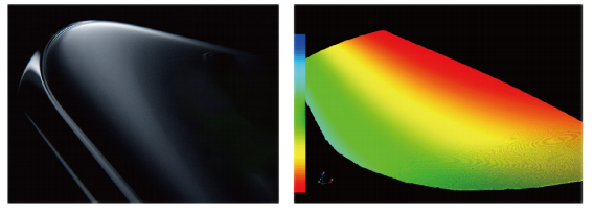

Material - independent and Reflectivity - proof

It is capable of detecting objects composed of almost all materials. Moreover, it enables high – precision measurement of objects featuring high reflectivity.

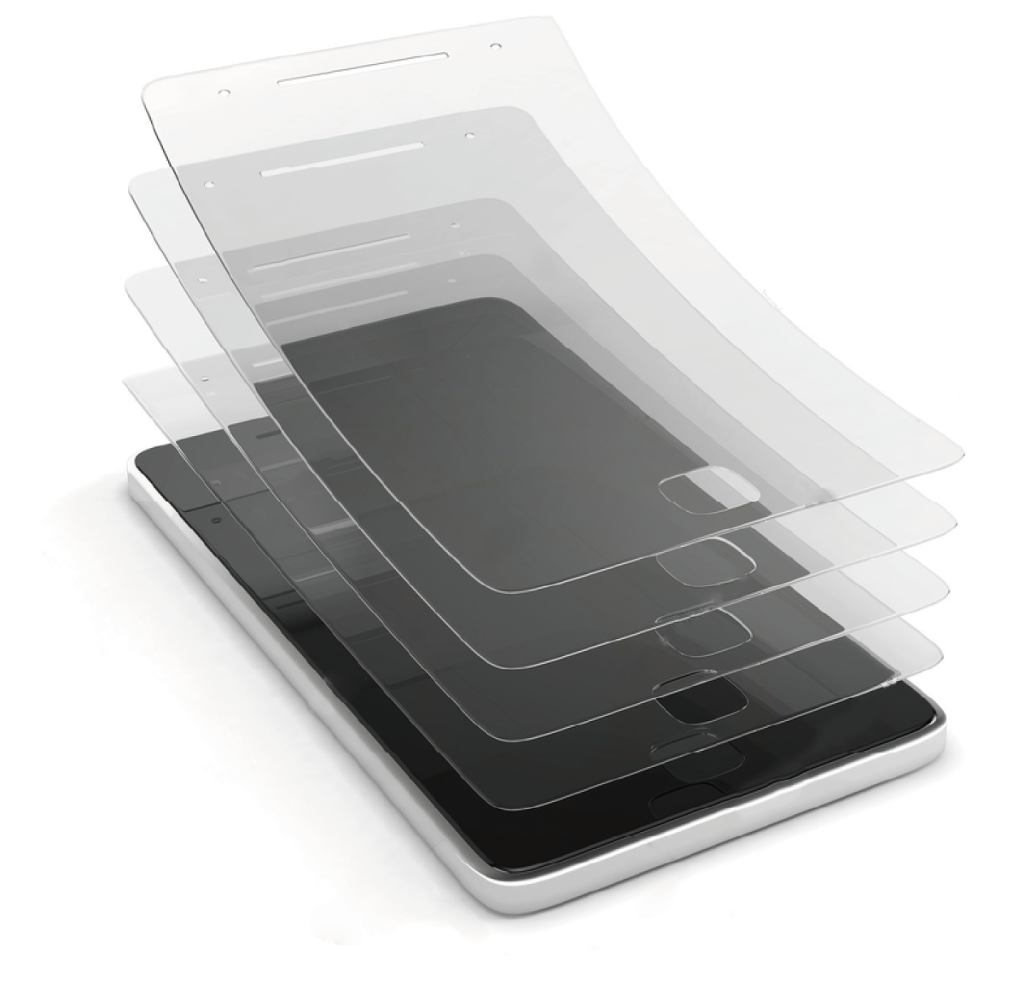

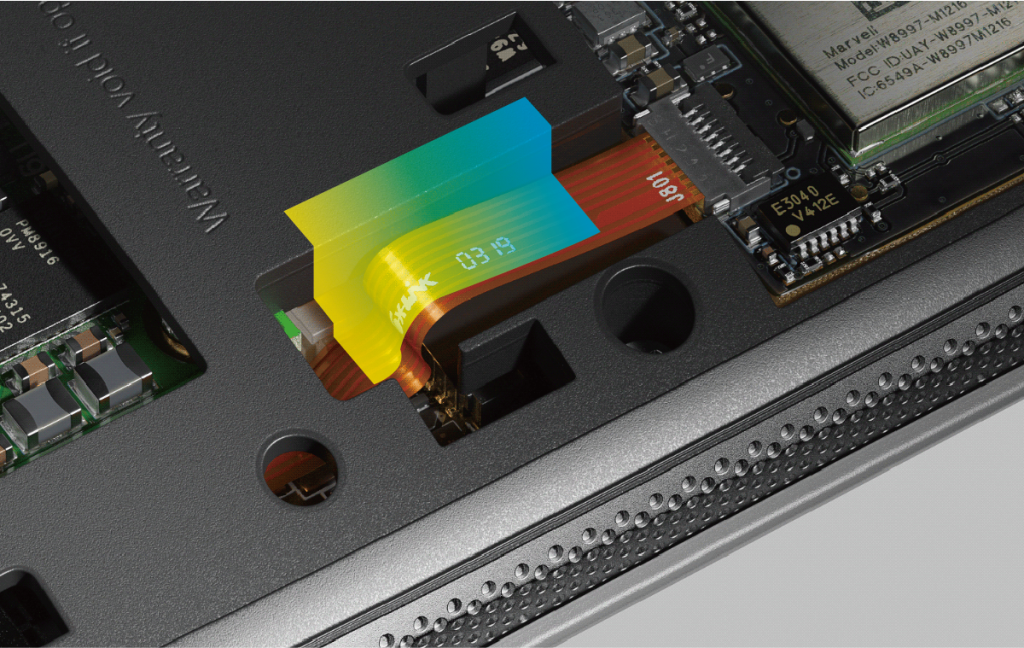

Multi - layer Measurement

- Hyperson 3D line spectrum confocal sensor’s unique line spectrum confocal scanning technology can construct 2D and 3D data of multiple transparent layers by scanning the display surface at one time.

- Provides excellent scanning performance on glass surfaces and curved edges (±20.5°) regardless of glass thickness, and accurate in-line defect detection such as chipping and cracks.

3D glass/edge seam dispensing inspection

- The excellent performance of Hyperson’s 3D line spectrum confocal sensor enables it to clearly detect defects such as scratches, unevenness, and mismatched contour features on the surface of the incoming material on high-speed assembly lines.

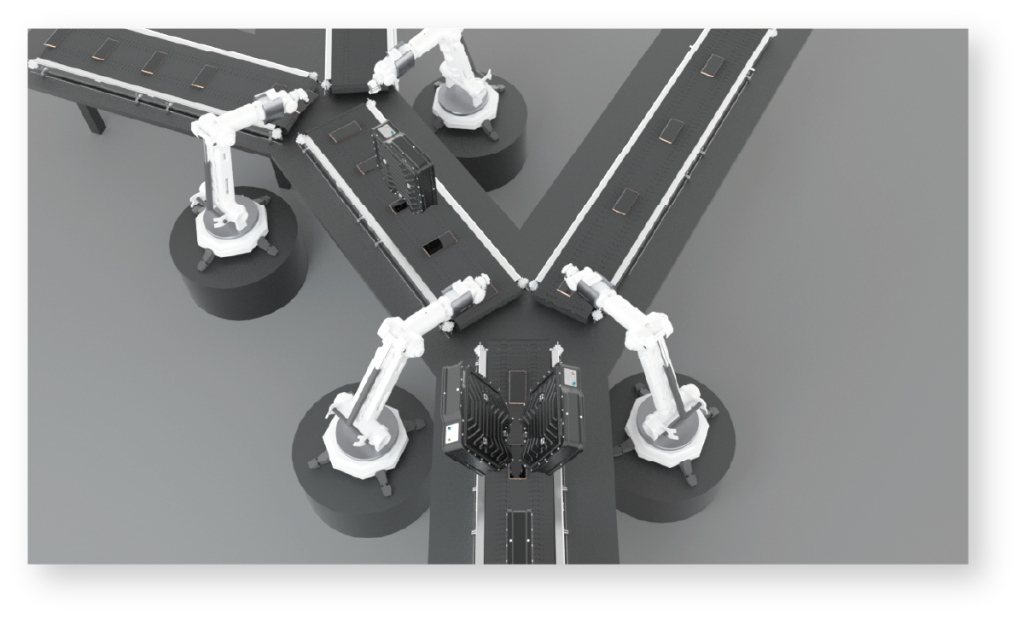

Line scan confocal / one step

- Hyperson 3D line spectrum confocal sensor has unique line confocal scanning technology.

By scanning the surface of the object under test once, various forms of appearance images and detailed original data can be exported.

• 3D point cloud image

• 2D contour drawing

• HD depth map

• HD grayscale images

Detailed data and high-quality raw images are perfectly matched to integrated equipment and complex measurements.

2048 Points/line

- Hyperson’s 3D line spectrum confocal sensor uses 2048 points/line and a minimum interval of 1.1μm, which can present the shape of the target object in detail, and can also achieve appearance inspections such as subtle depressions and bulges.

- The Z-axis repeatability is up to 0.4μm, and the ultra-high precision provides you with faster and more accurate measurement results.

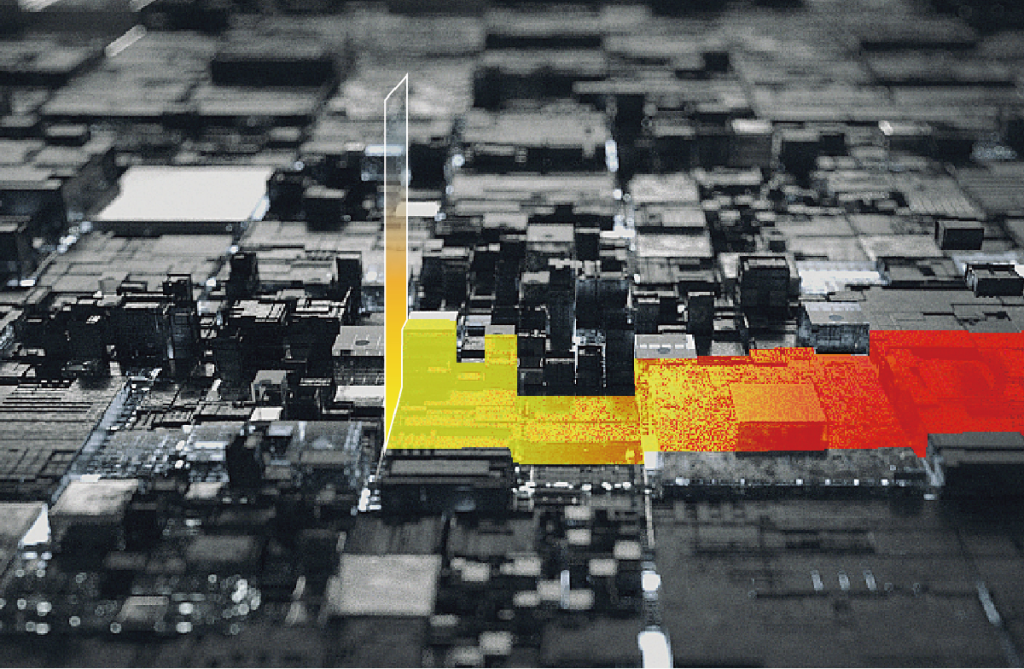

35,000 Lines/s, Ultra-high-speed Scanning

- Hyperson’s 3D line spectrum confocal sensor has an ultra-high-speed scanning speed of up to 35,000 lines/second, and is easy to integrate into customized detection systems. It can be perfectly used in factory assembly lines/complex and high-volume high-precision scanning scenarios to achieve multi-directional 3D imaging analysis of object surfaces.

3D topography/2D contour detection

Hyperson’s 3D line spectrum confocal sensor has a built-in efficient AI image recognition algorithm, which can not only complete feature recognition of object plane contours, but also measure height and depth data, and has a wide range of applications.

• Size

• Morphology

• Defect

• Fault

• Glitch and flicker

• Clearances and Surface Differences

• Surface Roughness

• Flatness

• Thickness

• Break height

• Volume

• Scope

Complete SDK and One-stop Software Services

- Easy to install and not restricted by place or purpose

- The program setting is intelligent, the page menu is concise and clear, and the operation is simple and easy to use.

- Tailor-made, worry-free after-sales service

±45° Large Measuring Angle

- Coaxial structure design, the incident light and the detected light follow the same path, there is no angle difference, the detection is highly real-time, and it is suitable for the measurement of various geometric shapes and surfaces with large tilt angles.

| Model | Line Length(mm) | X Direction Resolution (μm) | Repeatability in Z direction (μm) | Measuring Range(mm) | Scan Rate at Full Range (Hz) |

|---|---|---|---|---|---|

| HPS-LCX1000 | 2.3 | 1.1 | 0.1 | 1.4 | 6500 |

| HPS-LCX3000 | 10 | 4.9 | 0.4 | 6 | 5000 |