3D Optical Profilometer

- Detection without blind spots takes less than a second

- 2D/3D measurement done in one go

1μm Ultra-high Repeatability

20μm Absolute Measurement Accuracy

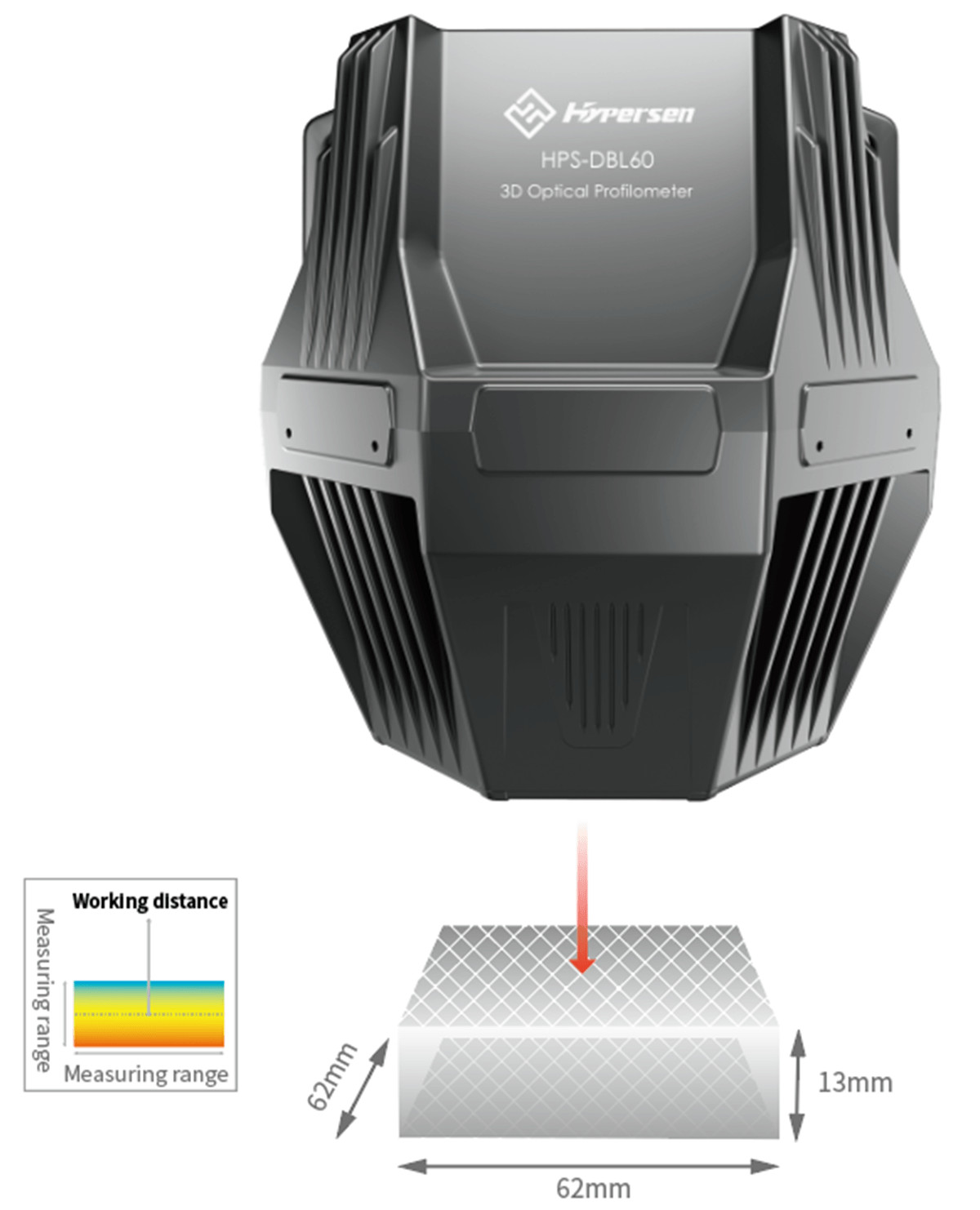

62mmx62mm Super Large Field of View

Ultra-high-speed Dynamic Measurement

Output 2D/3D Images Simultaneously

Complete SDK and one-stop support

Product Description

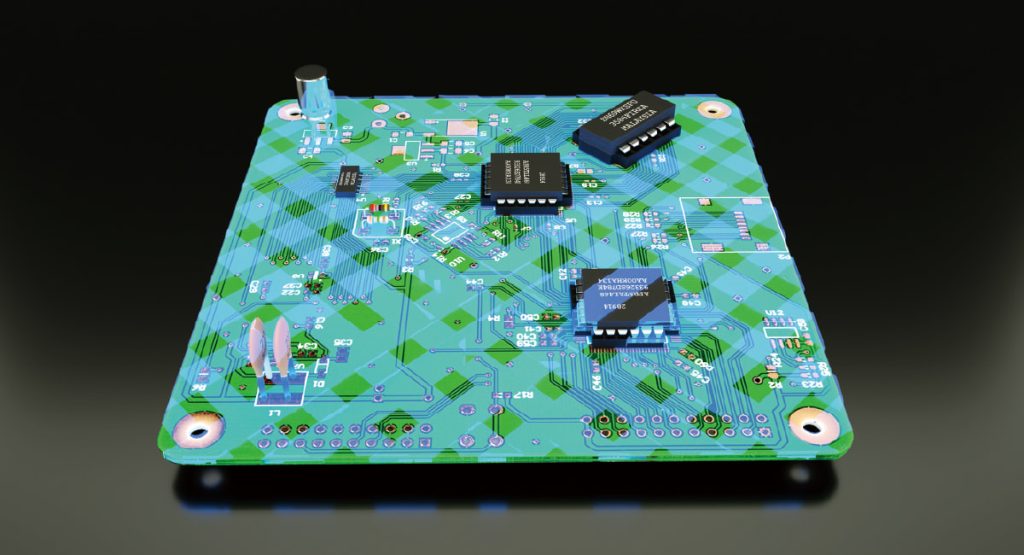

- Hyperson HPS-DBL series is a 3D visual inspection sensor using new flash detection technology. It has the characteristics of high recognition accuracy, wide measurement field of view and fast detection cycle.

- The HPS-DBL series sensor head is equipped with a high-performance vision controller and connected to 40G optical fiber to complete high-speed data transmission. It can complete high-precision online measurement of the 2D size and 3D shape of the object under test in less than one second. It is suitable for 3D inspection applications of various 3C, semiconductor, PCB, precision workpiece and other materials.

Sensing head

Controller

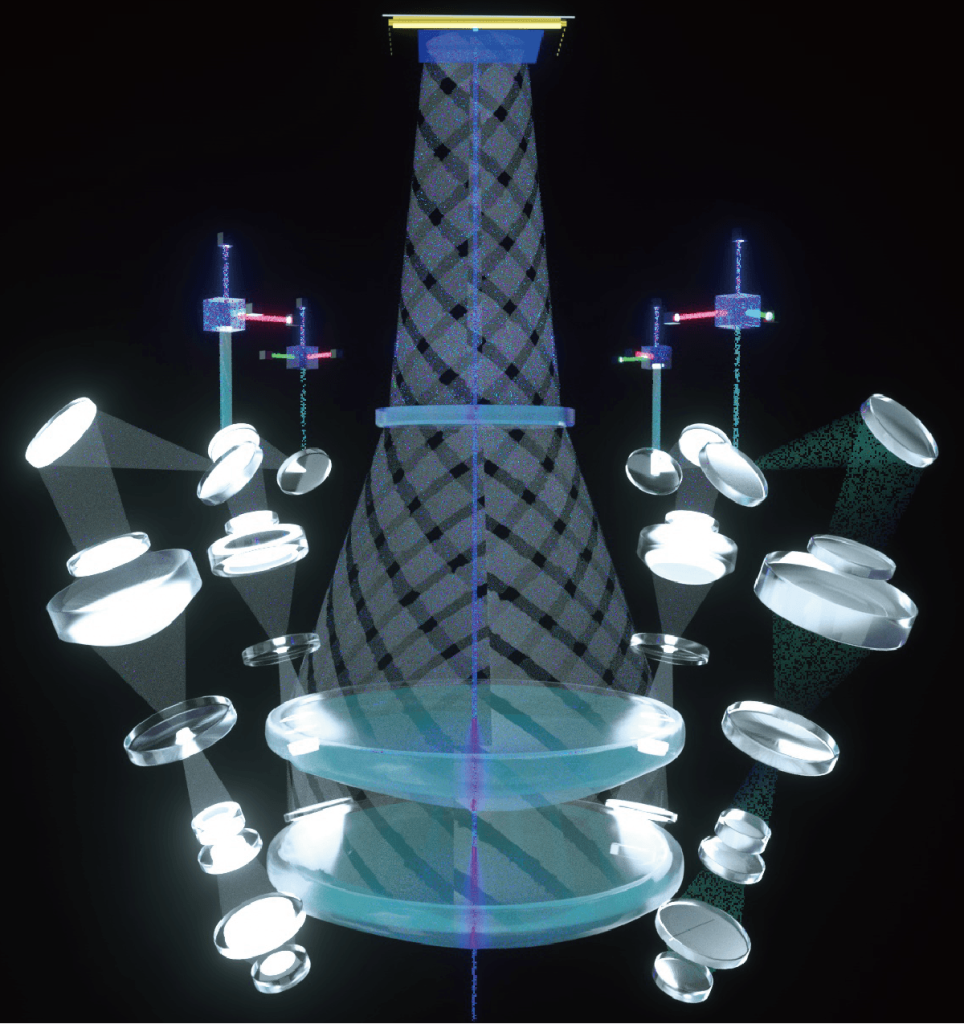

Principle Introduction

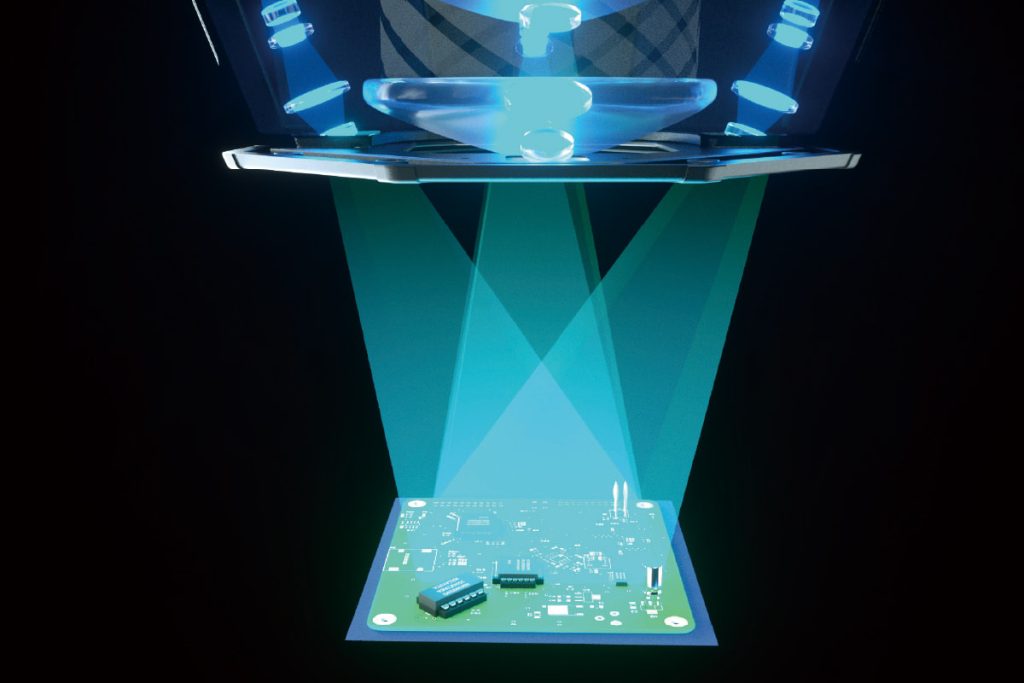

- The Hyperson 3D flash sensor HPS-DBL series uses an ultra-high-speed projection method to project special patterns of different wavelengths onto the measurement object, and collects pattern information on the object surface. It works with the Hyperson HPS-NB3200 high-performance vision controller and built-in AI decoding algorithm to process the data in real time to quickly obtain full-view color high-precision 2D images and 3D point clouds.

- Because the projection unit is four-in-one, it can effectively collect patterns even if there are complex depth changes on the surface of the object to be measured, which means that the detection is truly without blind spots.

Product Advantages

High-precision online 3D inspection

- Using the industry’s top CMOS photosensitive element and ultra-low distortion telecentric optical system, you can obtain XYZ three-dimensional high-precision data of the measured workpiece in one shot.

- Under high-speed real-time detection, it can also achieve 20um absolute measurement accuracy and 1um repeatability.

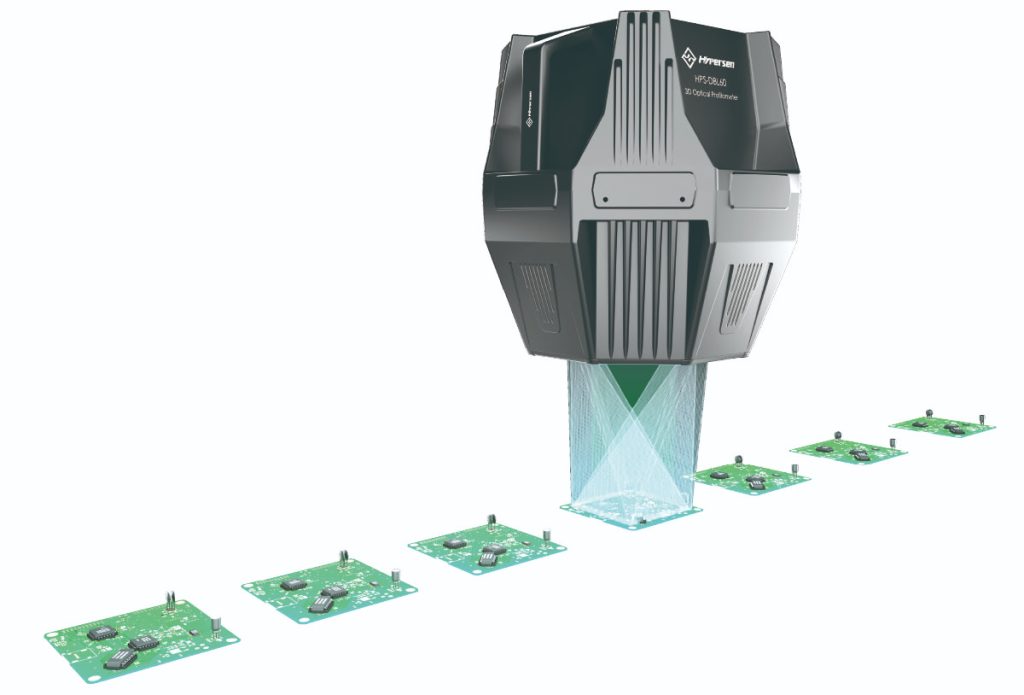

Large field of view, area detection, full coverage, no blind spots

- It adopts a symmetrical multi-angle projection unit, which is not restricted by the direction and detects no blind spots.

- It can not only detect the 2D size of the workpiece, but also measure the 3D contour, volume and height of the workpiece. The detection surface has a field of view of 62mmx62mm, which is suitable for large-scale measurement scenarios.

Ultra-high-speed dynamic measurement

- 40G Ethernet optical fiber is used for high-speed data transmission between the sensor head and the matching high-performance controller HPS-NB3200. High-precision 2D size and 3D contour results can be obtained in less than one second, which is suitable for high-speed online inspection applications.

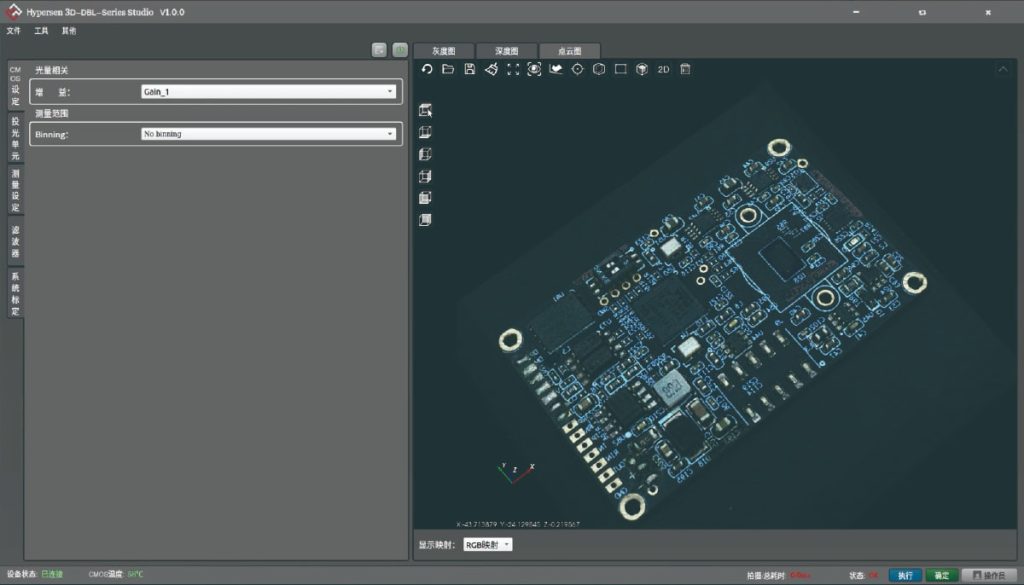

Efficient AI software algorithm package

Complete SDK and one-stop software support

- XY interval averaging processing controls individual differences in imaging systems.

- New 3D contour processing and 2D image optimization algorithms.

- Self-developed lighting algorithm can reduce the impact of multiple reflections and reduce invalid pixels in glossy areas.

- The system is simple and easy to integrate; it is small in size and easy to install and use.

| model | Repeatability (σ) | Measurement accuracy (height difference/width) | Field of view (mm) | Measuring range(mm) | working distance |

|---|---|---|---|---|---|

| HPS-DBL60S | 1μm | ±20μm | 60.5x60.5 | ±6.5 | 195mm |

| HPS-DBL60 | 1μm | ±20μm | 62x62 | ±6.5 | |

| HPS-DBL25 | 0.5μm | ±10μm | 25x25 | ±2.2 |