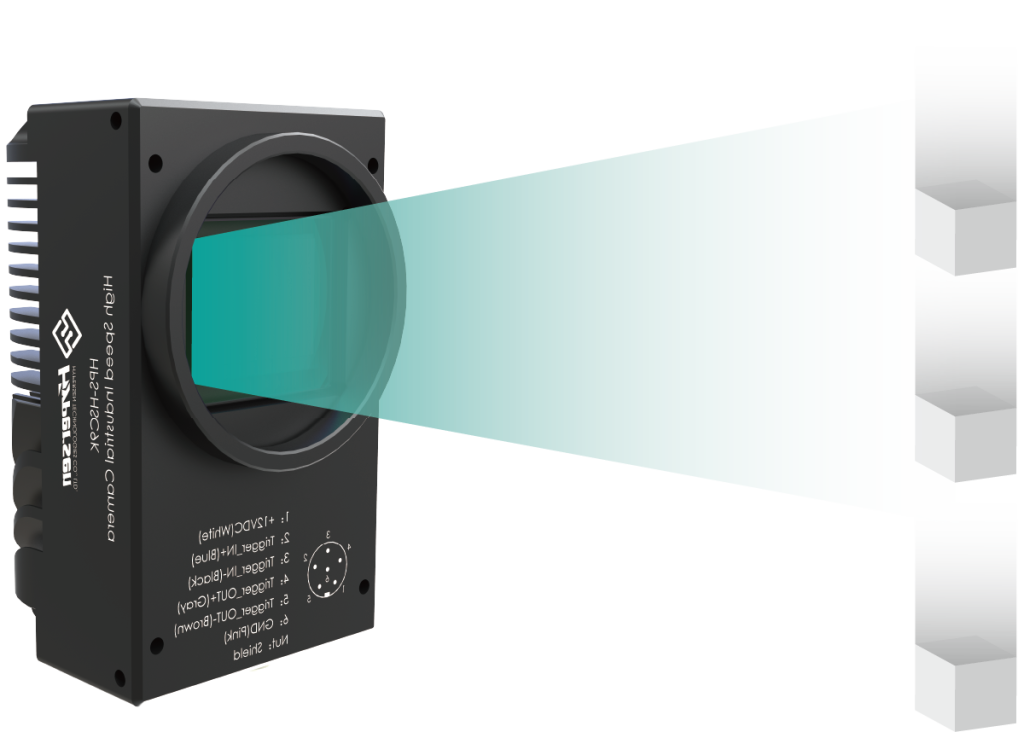

High Speed Industrial Camera

More than fast

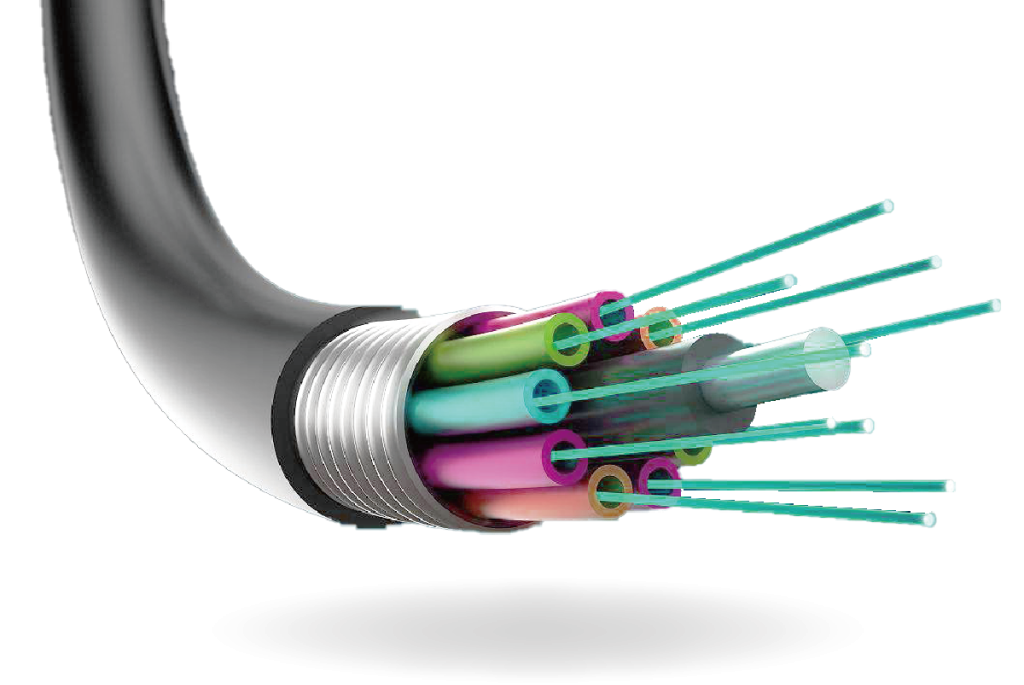

10G/40G Ethernet optical fiber ultra-high-speed transmission, real-time, synchronized 65.4 million ultra-high-speed pixels

10G/40G Ethernet optical fiber ultra-high-speed transmission

Standard C/M58/M72 interface

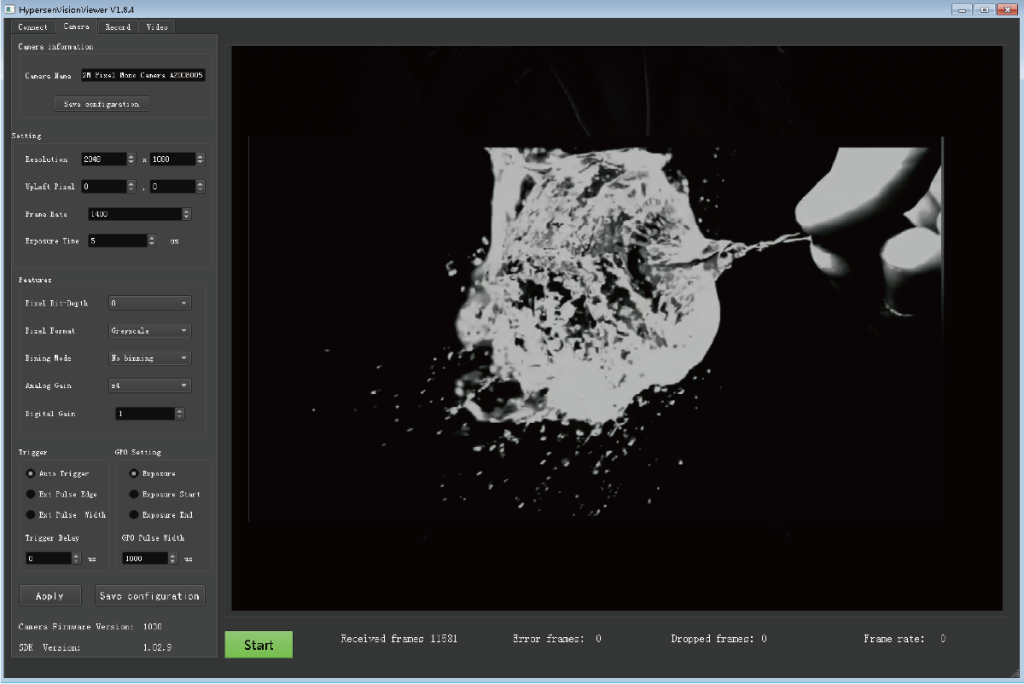

Complete one-stop software support service

Supports Genlcam GenTL standard and HPS-HSC SDK secondary development software package to facilitate user integration or secondary development.

Product Description

- The HPS-HS series of ultra-high-speed industrial cameras adopts the industry’s top ultra-high-speed image sensor, which features large pixel size, low noise, ultra-high frame rate, and long-distance transmission.

- The camera uses a 10G/40G Ethernet optical fiber interface, supports Genlcam GenTL standard and HPS-HSC SDK, and is easy to install and use. Suitable for machine vision, high-speed industrial inspection, high-speed motion analysis and other application fields.

High-Speed Area Scan Camera

- HPS series

HPS-HSC 2K:1490fps @2048*1080 8bit297lfps @1024*1024 8bit - HPS-HSC 5K:150fps @5120*5120 8bit240fps @3200*3200 8bit

- HPS-HSC9K:7lfps @9344*7000 Mono 8bit

High-Speed Line Scan Camera

HPS-HSL4K:

Resolution:4096

Line frequency: single line180kHz

HPS-HSL8K:

Resolution:8192×2

Line frequency: single line200kHz

HPS-HSL16K:

Resolution:16384×2

Line frequency: single line80kHz

Principle Introduction

- The high-speed moving target is illuminated by natural light or artificial auxiliary lighting to produce reflected light, or the moving target itself emits light, and part of this light passes through the imaging objective lens of the high-speed imaging system. After being imaged by the objective lens, it falls on the image sensing surface of the photoelectric imaging device. The photoelectric device controlled by the driving circuit will respond quickly to the target image on the image sensing surface. That is, according to the distribution of the target image light energy on the image sensing surface, a response-sized charge packet is generated at each sampling point, that is, the pixel point, to complete the photoelectric conversion of the image. Individual charge packets with image information are quickly transferred to readout registers. The read signal is transmitted to the computer after signal processing, and the computer reads, displays and interprets the image, and outputs the result.

- Therefore, a complete high-speed imaging system consists of optical imaging, photoelectric imaging, signal transmission, control, image storage and processing.

Product Advantages

Synchronous transmission without time difference

- The HPS-HS series uses 10G/40G Ethernet optical fiber, and synchronous transmission without time difference can meet the stringent requirements for real-time and synchronization in industrial vision applications.

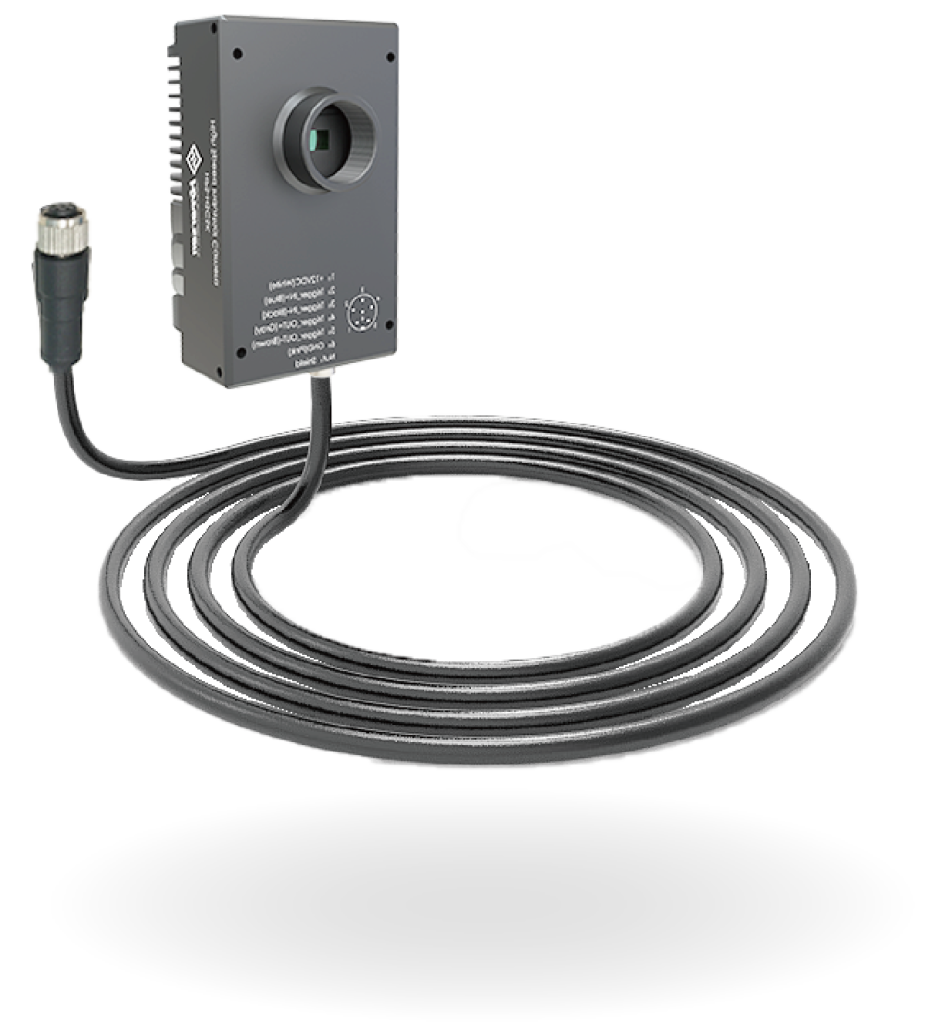

Highly integrated design

- HPS-HSC2K/5K ultra-high-speed industrial cameras use standard C interface for easy lens installation and wide applicability; 9K/4K use standard M58 interface. HPS-HSL4K uses the standard M58 interface, and HPS-HSL8K/16K uses the M72 standard interface.

- Using the industry’s top CMOS image sensor chip and ultra-high-speed FPGA to ensure the best image quality, stability and transmission efficiency;

- Aviation aluminum full metal shell design, sturdy and durable and maintains good heat dissipation performance;

- Use aviation grade plugs and sockets. Stable and reliable.

Complete one-stop software support service

- HPS series ultra-high-speed industrial cameras support Genlcam GenTL standard and HPS series SDK secondary development software package, which facilitates user integration or secondary development.

Ultra-high frame rate/ultra-long distance/ultra-low noise

- HPSseries HPS-HSC2K:1490fps@2048*1080 8bit

2971fps@1024*1024 8bit

HPS-HSC 5K: 150fps@5120*5120 8bit

240fps@3200*3200 8bit

HPS-HSC 9K:7lfps@9344*7000 Mono 8bit - Optional 3m/5m/10m optical fiber

High-Speed Line Scan Camera

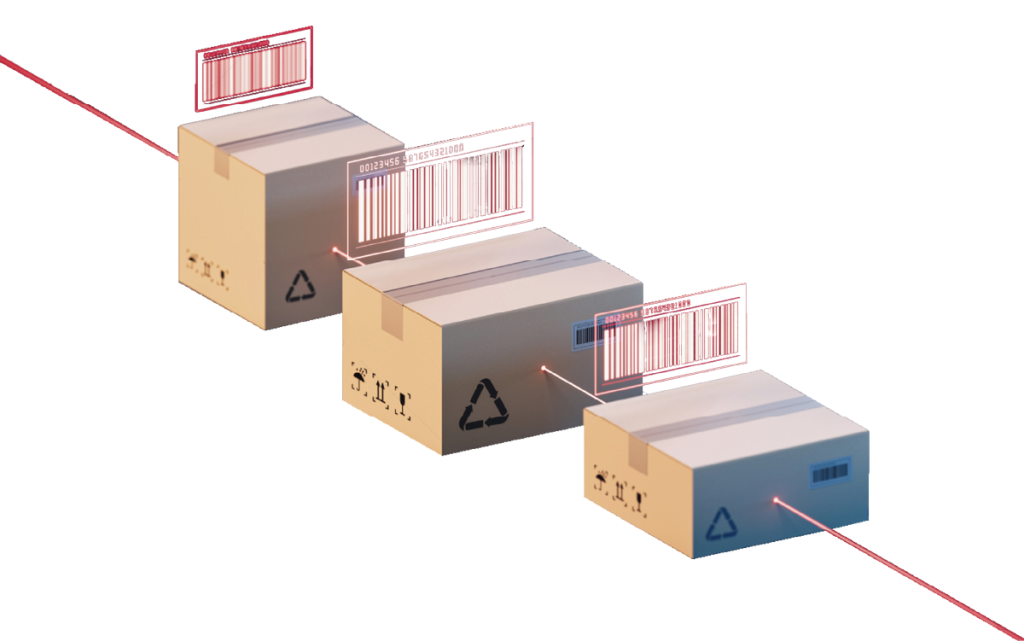

- Line array cameras use line array image sensors, and the detection method is “line” shaped. It has the characteristics of fast scanning speed, large field of view and high precision. It is often used to detect materials with continuous or slender fields of view, such as printing machinery, plastics, metals and fibers.

- Usually, the object to be inspected keeps moving at a constant speed, and one or more cameras are used to continuously scan it line by line. This can complete uniform detection of the entire surface of the object. By comparing it with a flawless reference object, an alarm is triggered after detecting defects.

- In addition, mail sorting, barcode, QR code, line of text (OCR) and other code reading are all common inspection applications for line scan cameras.

200K lines/second ultra-fast collection speed

- The acquisition speed of the HPS-HSL line array camera is 200K lines/second. The faster acquisition speed can meet the needs of various high-demand applications – such as material classification and inspection, traffic safety, and various general machine vision applications.

higher resolution

- With ultra-high resolution of 16384 pixels and a pixel size of only 3.5umx3.5um, the HPS-HSL series can achieve large-format zero-distortion high-resolution imaging and is widely used in printed products, calligraphy and painting cultural relics, large glass, LCD panel inspection, PCB inspection, steel inspection, tobacco industry, textile industry, panel furniture, tents, sailboats, diving suits, clothing and other fields.

| model | resolution | Target surface/pixel size | Continuous data transfer rate |

|---|---|---|---|

| HPS-HSC2K | 2048x1080(px:6μmx6μm) | 1in(12.3mmx6.5mm) | 1490hz/s@220Wpx,8bit 2971hz/s@100Wpx,8bit |

| HPS-HSC5K | 5120x5120(px:2.5μmx2.5μm) | 1.1in(12.8mmx12.8mm) | 150hz/s@2500Wpx,8bit 240hz/s@1000W px,8bit |

| HPS-HSC9K | 9344x7000(px:3.2μmx3.2μm) | 2.3in(29.9mmx22.4mm) | 71hz/s@6500Wpx,Mono 8bit |

| HPS-HSL4K | 4096 | 7μmx7μm | \ |

| HPS-HSL8K | 8192x2 | 7μmx7μm | \ |

| HPS-HSL16K | 16384x2 | 3.5μmx3.5μm | \ |