Laser calibration sensor

High repeatability and reliability

Integrated design, compact structure

All signal communication is concentrated on one interface, making wiring simple Easy to install

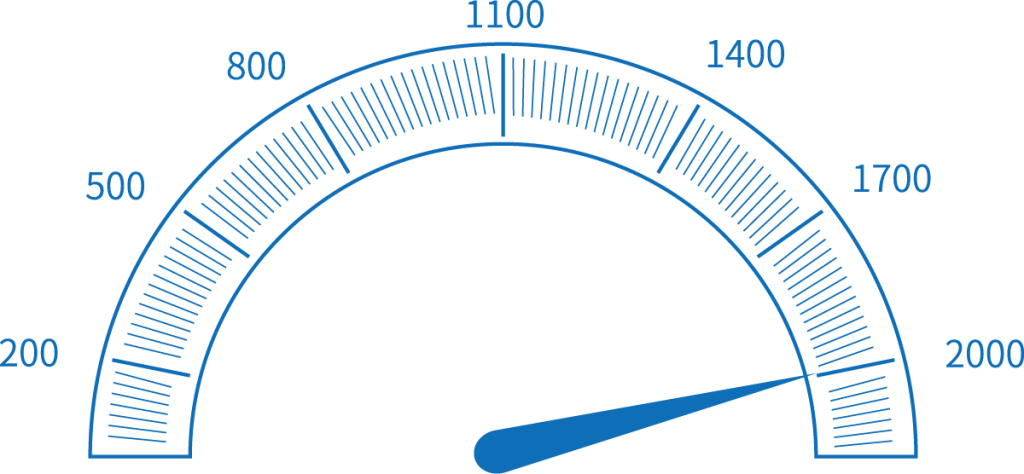

Extremely short response time

Switch detection frequency can reach 2kHz

IP67 industrial grade protection

High repeatability and reliability

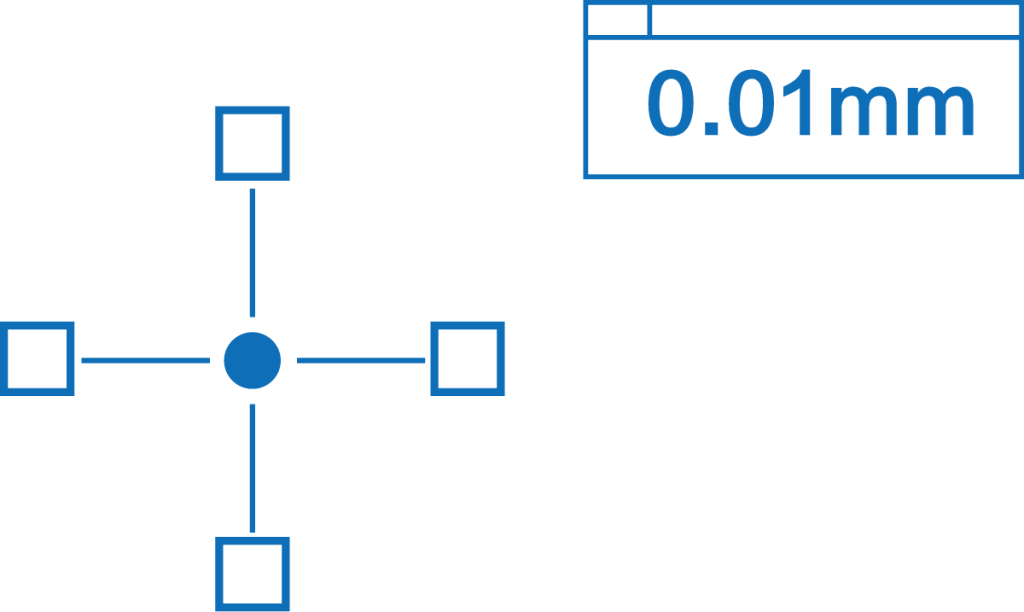

Repeat accuracy up to 0.01mm

Backlight compensation

Can realize automatic background light compensation and resist strong light interference

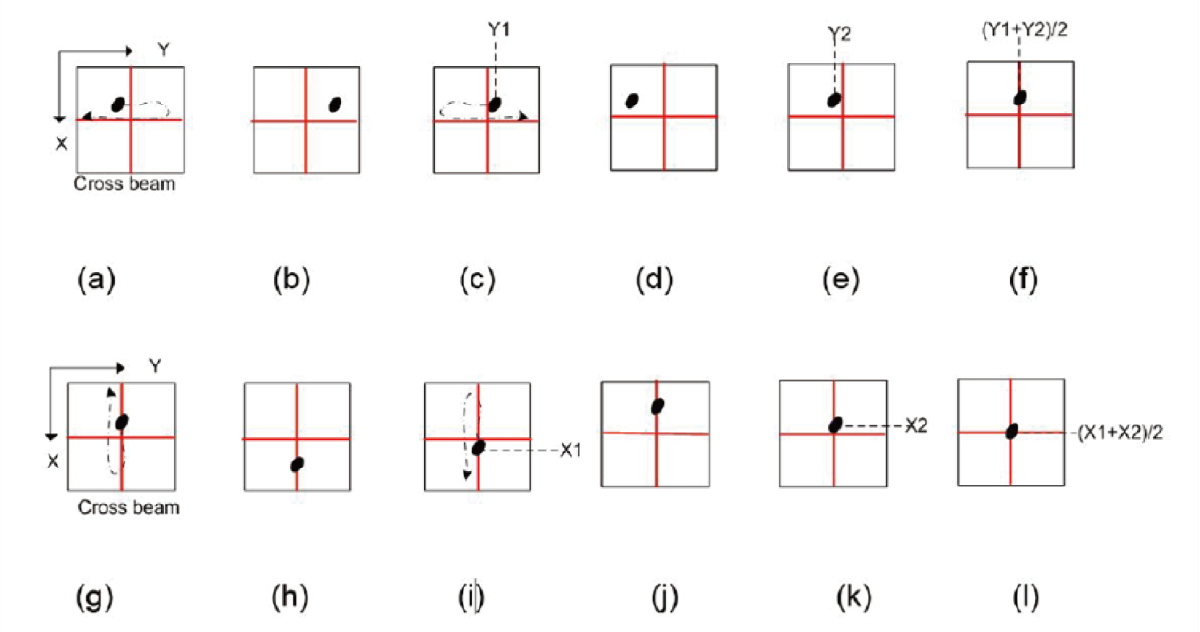

Three axes at the same school

Three coordinates can be calibrated at the same time, and the XY and Z axes can be accurately positioned at the same time. There is no need to calibrate the product after installation.

Product Description

- The HPS-TCP series sensor is a high-precision laser sensor used for robot calibration and positioning in industrial applications. It can achieve absolute position correction and zero point reset along spatial coordinates, and has good overload resistance and durability.

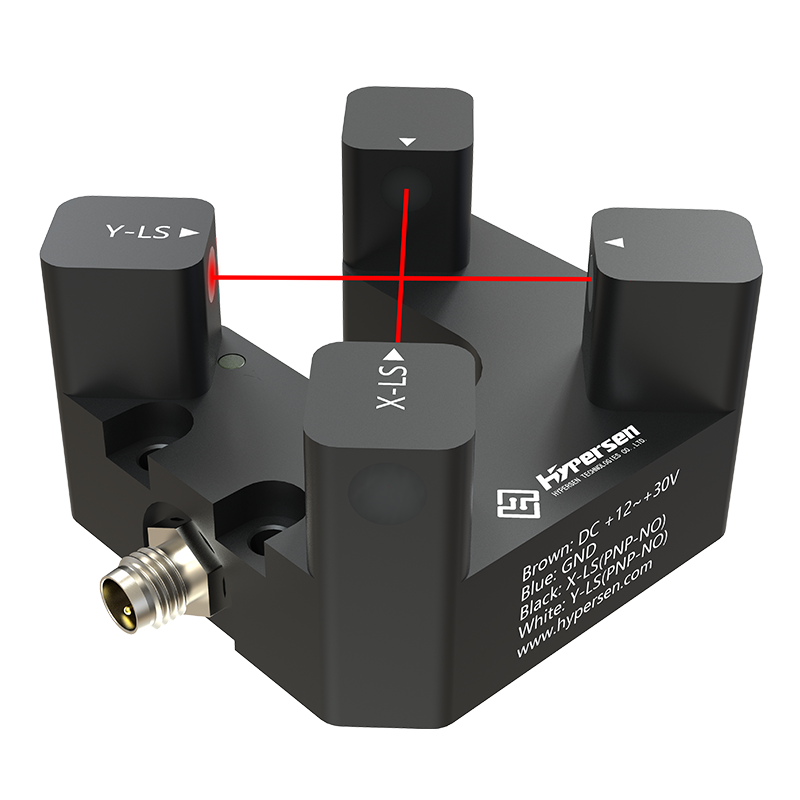

- HPS-LCB02 is a laser pointer sensor used for high-precision positioning in industrial applications. It can achieve absolute position correction and zero-point reset along the three dimensions of the sensor, X, Y, and Z. It has IP67 industrial-grade protection and has good impact resistance and durability. It is widely used in dispensing machine needle positioning, CNC tool positioning, industrial robot positioning and other scenarios.

Laser needle sensor

HPS-LCB02 is a high-precision laser pointer sensor used for industrial positioning. It can achieve absolute position correction and zero point reset along the three dimensions of the sensor, X, Y, and Z. It has good impact resistance and durability.

Principle Introduction

- Hardware that can provide force and torque feedback in three directions is widely used in different scenarios such as robot control, mechanical experiments, and scientific research. Unlike other common single-dimensional and three-dimensional force sensors, the six-dimensional force sensor can measure complete six degrees of freedom environmental force data, making it suitable for more applications.

- The six-dimensional force sensor gives the robot a real “touch” and enables closed-loop feedback with the robot’s action posture and visual system, improving accuracy and flexibility. Quickly and accurately adapt to the surface contour and consistency of the processed materials or parts, effectively improving the processing effect. Improving product quality and shortening cycle time have the effect of reducing costs and increasing efficiency.

- Since the six-dimensional force sensor is often installed at the end of the manipulator, the six-dimensional force sensor is applied at the end with high force control accuracy and low development difficulty, but the control bandwidth is narrow. Therefore, when the rhythm requirement is high, we need to perform initial positioning through vision first, and then use the six-dimensional force sensor together. This can not only ensure high-precision operation, but also make up for the shortcomings of insufficient rhythm.

Product Advantages

Ultra-small light spot, repeatability up to 0.01mm

- HPS-LCB02 has ultra-high measurement accuracy. The 30um ultra-small light spot enables the repeatability to reach 0.01mm.

Very short response time, detection frequency up to 2kHz

- HPS-LCB02 has ultra-fast response time and detection frequency up to 2kHz

Integrated design, simple wiring, compact structure

- HPS-LCB02不仅可以双轴同校,且可同时校准三个坐标,X、Y和Z轴同时精确定位产品安装后无需在进行校准,并所有信号通讯集中在一个接口,布线简单,安装便捷。

Background light compensation algorithm to resist strong light interference

- HPS-LCB02 has a built-in background light compensation algorithm, which can resist strong light interference and improve the reliability of the sensor. And the whole body can reach IP67 industrial grade protection.

Designed with IP67 protection level, it is dustproof, waterproof, stable and reliable.

| model | resolvable object diameter | Repeat accuracy |

|---|---|---|

| HPS-LCB02 | 0.2mm | <0.01mm |

| HPS-TCP120 | 5μm | |

| HPS-TCP100 | 10μm |