“Both Linear and Area Arrays Covered”, Hypersen’s New Ultra-high-speed Industrial Cameras Empower Machine AI Vision

- hypersenadmin

- Company News

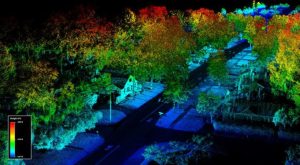

Against the backdrop of Industry 4.0, intelligent manufacturing has become a hot topic in the industrial field. To meet the demands of a faster, more efficient, and more complex production environment, machines have been equipped with more “senses” that can replace human functions – sensors. Among them, the wide application of high-speed industrial cameras on factory production lines is a typical example of empowering machines with vision.

High-speed industrial cameras have a wide range of applications and can be used in production inspection, printing, electronics, electrical manufacturing, and industries with higher requirements. In the industrial field, for example, when testing the anti-collision performance of mobile phone cases, it is necessary to simulate real drop scenarios. The entire dropping process only takes one to two seconds, and the time from the moment the phone hits the ground to when the appearance of the phone case deforms or breaks is calculated in microseconds. The human eye cannot capture these instant images. Especially when the object is made of fragile materials like glass, it is necessary to observe the direction and state of internal cracks generated when the material is impacted. In such cases, high-speed industrial cameras are needed as a carrier to analyze the structure of the material when it is damaged.

Hypersen, as a practitioner in shaping domestic high-end intelligent sensor brands, is dedicated to craftsmanship and independent research and development. In the fourth quarter of 2021, it launched two high-performance ultra-high-speed industrial cameras, including linear array industrial cameras and area array industrial cameras, to empower industrial intelligent manufacturing with machine AI vision. Let’s briefly introduce them below.

| New Product | Introduction | Advantages | Application Fields |

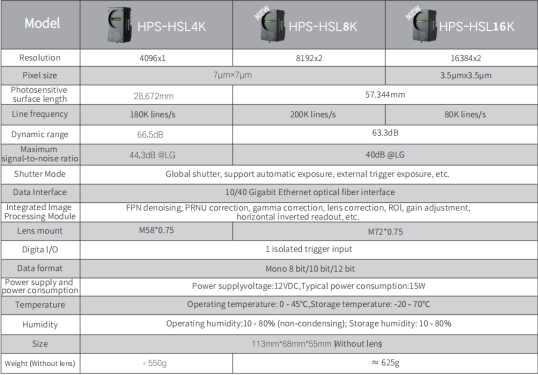

| HPS-HSL4K | Adopts a high-speed 4096-pixel linear array black-and-white image sensor. | Global shutter, M58 lens interface, 10G fiber optic transmission, 7μm * 7μm, 4096 * 2 lines, line frequency up to 180k lines per second, complete SDK and software support. | One-dimensional dynamic target measurement, mainly used in image processing in industrial, medical, scientific research, and security fields, meeting the needs of defect detection, positioning, recognition, and measurement applications. |

| HPS-HSC9K | Adopts a 65 million-pixel black-and-white area array high-speed image sensor. | Global shutter, large target surface, M58 lens interface, 40G fiber optic transmission, 3.2″ CMOS, 2.5μm x 2.5μm, frame rate up to 71fps at a resolution of 9344 * 7000, complete SDK and software support. | Two-dimensional dynamic target measurement, such as the measurement of area, shape, size, position, and even temperature, suitable for high-speed and high-precision machine vision detection and motion control related applications in industrial, medical, and scientific research fields. |

Product Technical Parameters:

Currently, Hypersen’s ultra-high-speed industrial camera product line covers two major categories, linear array and area array, with four products in total, meeting the needs of multiple fields in industrial machine vision. Besides the above two new products, there is also the HPS-HSC2K ultra-high-speed industrial camera, which adopts the industry’s top 2.2 million-pixel black-and-white high-speed image sensor, with a global shutter, a standard C lens interface, 40G fiber optic transmission, and a frame rate of up to 1490fps at a resolution of 2048 * 1080. And the HPS-HSC5K ultra-high-speed industrial camera adopts a 25 million-pixel black-and-white image sensor, with a global shutter, a standard C lens interface, 40G fiber optic transmission, and a frame rate of up to 150fps at a resolution of 5120 * 5120. For more product information, application cases, and videos, please click to return to the home page to learn more.