6-Axis Force/Torque Sensing: Working Principles, Types, and Industrial Implementations

- hypersenadmin

Force and Torque Fundamentals: Principles and Classification of Torque Sensors

1. Definition and Key Differences Between Force and Torque

1.1 Force

- Definition: An interaction between objects that can change their motion state or cause deformation.

- Key Characteristics:

- Vector quantity (magnitude and direction), measured in Newtons (N)

- Point of application affects results (e.g., pushing a door at different positions creates varying effects)

1.2 Torque

- Definition: The rotational effect produced by a force acting at a distance from a pivot point.

- Formula: M = F × L (Unit: N·m)

- Key Characteristics:

- Direction determined by right-hand rule

- Requires non-collinear forces to generate meaningful torque

1.3 Comparative Analysis

| Parameter | Force | Torque |

|---|---|---|

| Primary Effect | Linear motion (e.g., pushing objects) | Rotational motion (e.g., turning bolts) |

| Measurement Unit | Newton (N) | Newton-meter (N·m) |

2. Classification of Torque Sensors

2.1 By Measurement Dimensions

- 1-Axis: Measures single-direction torque (e.g., torque wrenches)

- 3-Axis: Measures torque in two orthogonal directions (e.g., robotic joint monitoring)

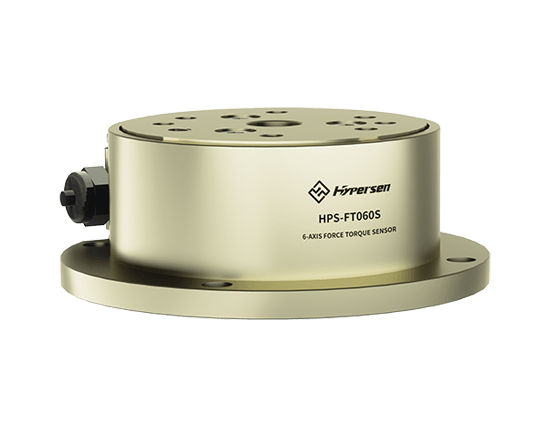

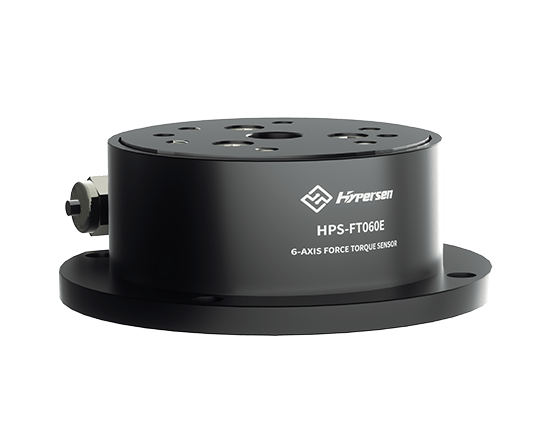

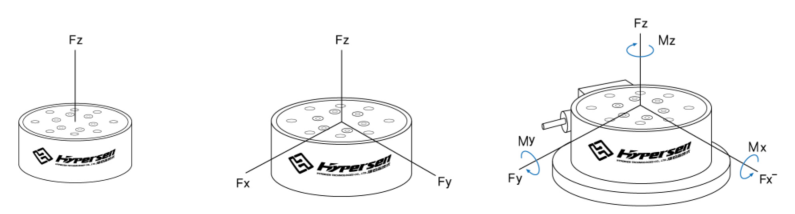

- 6-Axis: Simultaneously measures three linear forces (Fx, Fy, Fz) and three rotational moments (Mx, My, Mz) (e.g., Humanoid Robot Joints, Collaborative Robots, Medical Robots, etc.)

2.2 By Working Principle

| Type | Operating Principle | Key Features |

|---|---|---|

| Strain Gauge | Measures resistance changes in deformed strain elements | High accuracy (±0.25%FS), robust construction |

| Piezoelectric | Detects charge generation in piezoelectric crystals | Ultra-high frequency response (>30kHz) |

| Optical | Tracks displacement via light intensity modulation | Excellent EMI immunity, no electrical contact |

3. Industrial Applications

- Robotics: Force-controlled assembly, precision grinding/polishing

- Medical Technology: Haptic feedback in surgical robotics

- Industrial Automation: Docking force monitoring, actuator control systems

Technical Summary

As fundamental mechanical quantities, force and torque measurement enables advanced motion control across industries. 6-axis torque sensors have become indispensable in smart manufacturing due to their multidimensional measurement capability and sub-Newton precision. Strain gauge-based solutions currently dominate industrial applications, while piezoelectric and optical variants serve specialized high-performance needs.

This technical framework provides essential knowledge for engineers evaluating torque measurement solutions for robotic, industrial automation, or R&D applications. For specific implementation cases or custom sensor requirements, please consult with our technical team.

Note: All technical specifications represent typical industry standards. Actual product parameters may vary by manufacturer and application requirements.