Folding screen connection structure detection based on spectral confocal technology

- hypersenadmin

On March 1, the world’s latest folding screen mobile phone – Huawei’s vertical folding screen Pocket 2 was launched. This is the world’s 43rd mass-produced folding screen mobile phone since the launch of the first folding screen mobile phone in 2018. Major terminal manufacturers such as Samsung, Huawei, Xiaomi, OPPO, vivo, and Honor have emerged on the folding screen mobile phone track.

Source: Internet

Professional research institutions IDC and CINNO Research have both released statistical data on the folding screen mobile phone industry. Although there is a slight gap in the data collected by the two organizations, from an overall perspective, approximately 7 million folding screen mobile phones were shipped in the Chinese market last year, with a growth rate of more than 100%.

Consumers’ acceptance of foldable screen mobile phones continues to increase, and they also put forward more advanced requirements for the lightweight, durability, folding feel, screen flatness (crease reduction), etc. Among them, screen flatness (crease reduction) is the issue that attracts the most attention.

Source: Internet

Part One application test

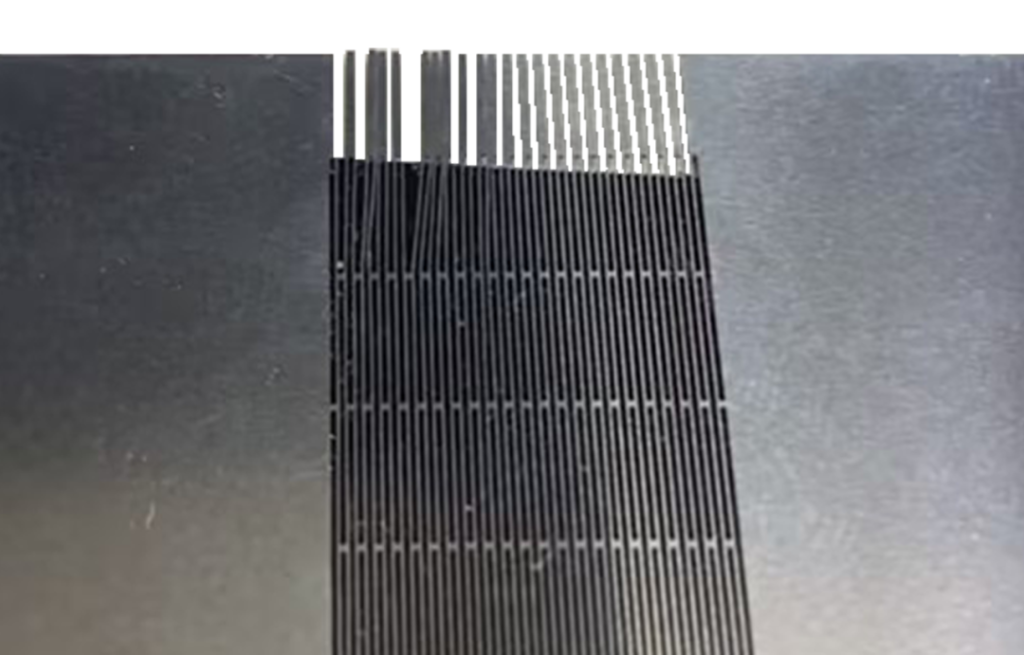

In addition to the hinge design, the screen creases of foldable mobile phones are also related to the screen structure. The sample measured this time comes from the flexible panel connection structure part.

Specific areas of the sample need to be coated with special materials in a specific arrangement. Due to the particularity of the materials, spectral confocal technology is required to achieve measurement. Considering range, accuracy, efficiency and other factors, we will choose the 3D line spectral confocal sensor HPS-LCX3000 based on spectral confocal technology for measurement.

01 Detect physical objects

02 Testing requirements

Product name: Folding screen connection structure

Measurement items: Appearance inspection

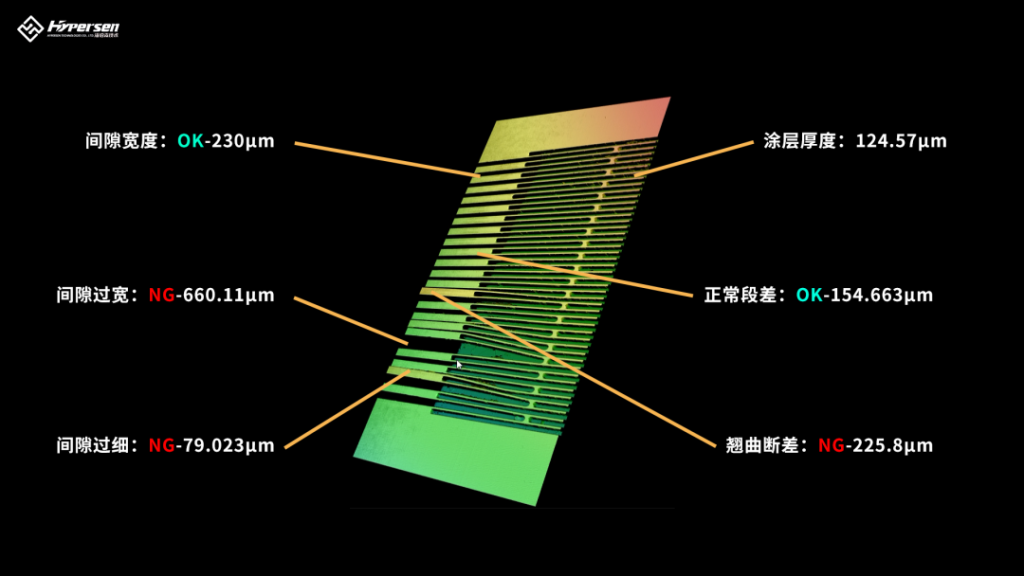

Measurement requirements: clearance, height, step difference, warpage

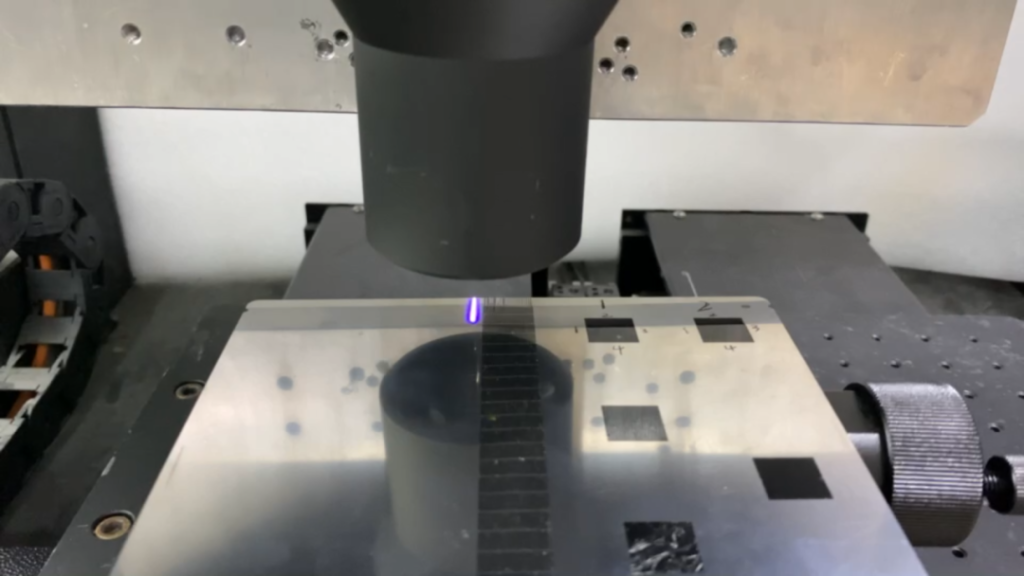

03 Detection process

The sample was scanned using the 3D line spectrum confocal sensor HPS-LCX3000.

The 3D line spectral confocal sensor HPS-LCX3000 is a non-contact optical detection sensor based on the principle of spectral confocal. It has a Z-axis repeatability of 0.4μm and an X-direction resolution of 4.9μm. It can record detailed raw data and generate various forms of 2D/3D images in one scan. It can complete high-precision 3D measurements of almost all material surfaces such as transparent, mirror, and highly reflective surfaces.

04 Test results

The above information can be obtained by using the Hyperson 3D line spectrum confocal sensor HPS-LCX3000 to precisely measure the sample.

Part Two Product Introduction

Hyperson HPS-LCX series is a non-contact optical precision measurement sensor based on the principle of spectral confocal method. It has the characteristics of fast detection speed, high imaging resolution and strong material adaptability.

01 Product advantages

The product uses line scanning CMOS imaging to achieve 3D feature analysis of the appearance of the object to be measured, technically breaking through the limitations of traditional detection methods, and the measurement process is not affected by the intensity of reflected light.

02 Industry Application

It effectively solves the industry’s problem of high-precision appearance inspection of transparent bodies, highly reflective mirrors, black rubber and other materials, and is suitable for online inspection applications in 3C electronics, semiconductors, automotive electronics, medical and scientific research and other fields.