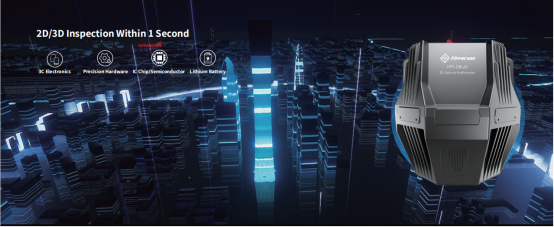

New Product Release: China’s the First 3D Optical Profilometer – “Big Pineapple”

- hypersenadmin

- Company News

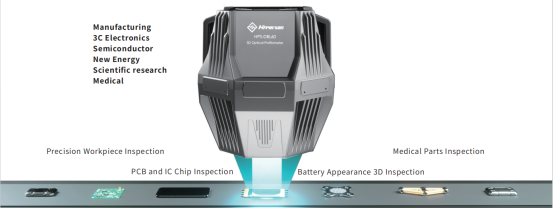

Following the widespread attention in the industry attracted by the release of China’s first 3D line confocal sensor in April last year, on April 18, 2022, Hypersen once again made a significant move in the field of 3D vision inspection by officially launching China’s first integrated 3D Optical profilometer – “Big Pineapple” HPS-DBL60.

New Product Premiere

This “pineapple” is no ordinary thing!

The HPS-DBL60 integrates optical, mechanical, electrical, and computing technologies and is an industrial-grade 2D/3D composite optical precision measurement sensor.

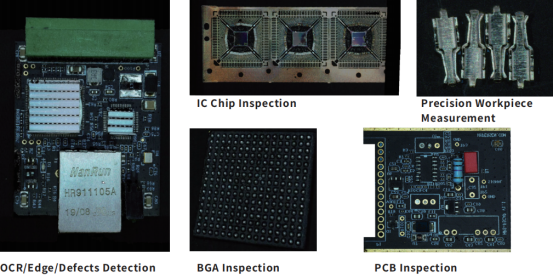

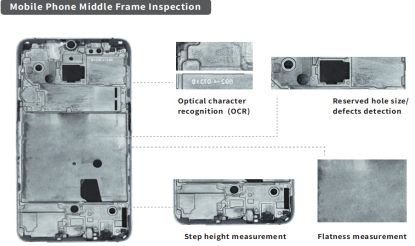

The product is equipped with a CMOS photosensitive element of the industry’s top level, a four-in-one high-speed color unit, and an ultra-low distortion telecentric optical system. It can complete the measurement of 2D dimensions and 3D contours in a working area of 62 * 62 mm in less than one second, with a repeat measurement accuracy reaching 1 μm. The specially optimized optical system and built-in algorithms have greatly enhanced its adaptability to the measured surfaces of highly reflective and black materials, making it suitable for high-precision online measurement of the 2D/3D appearance and dimensions of various 3C, semiconductor, PCB, precision workpieces, and other products.

“All-round Coverage”, Leaving No Detection Dead Angle

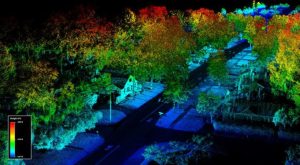

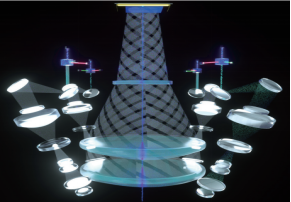

The HPS-DBL60 integrates a four-in-one color projection unit, which projects special patterns of different wavelengths onto the measurement object in a high-speed projection manner and collects the pattern information on the object’s surface. In cooperation with a high-performance vision controller and a built-in AI decoding algorithm, the data is processed in real time to quickly obtain full-view, high-color-precision 2D images and 3D point clouds.

“Sharp Eyes”, Leaving No Place for Defects to Hide

The specially optimized pixel microlens array of the HPS-DBL60 can effectively improve the photosensitivity, signal-to-noise ratio, and dynamic range of shooting. In addition, the ultra-low distortion telecentric optical system solves the problem of numerical deviations caused by position changes during the shooting process, greatly reducing the impact of image distortion. Even in a real-time dynamic measurement state, the HPS-DBL60 can achieve an absolute measurement accuracy of < 20 μm and a repeat measurement accuracy of < 1 μm.

Comprehensive Intelligence, Flexible Software Settings

The detection mode of the HPS-DBL60 can be changed as needed. The built-in algorithms can efficiently optimize the generated 2D images and 3D point clouds, and can detect and identify abnormal features through differential data to ensure the accurate measurement of characteristics such as size, volume, and height. Hypersen’s unique encoding and decoding algorithms and HDR high dynamic mode can effectively remove halos and shadows in 2D images, reduce surface gloss and bright spots, and improve the accuracy of 2D detection.

The HPS-DBL60 can complete the surface quality inspection of 2D/3D composites, effectively reducing the complexity of the detection system.

Ultra-fast Computation, Detection in Less Than One Second

The HPS-DBL60 adopts 40G Ethernet optical fibers for high-speed data transmission between the sensing head and the matching high-performance controller HPS-NB3200. The controller is internally equipped with an eight-core 64-bit CPU, a high-performance dedicated accelerator, and a high-speed FPGA, with a computing speed of up to 32 trillion operations per second. The built-in AI image decoding algorithm can achieve ultra-fast processing of 2D/3D data, shortening the time difference interval between image processing and continuous shooting and significantly enhancing the detection rhythm.

Easy to Integrate, with a Wide Range of Application Scenarios

The HPS-DBL60 adopts an integrated all-solid-state design with a compact structure, making it easy to integrate into the production line.

The product can effectively solve the problem of surface quality inspection of 2D/3D composites, achieving micron-level detection accuracy while significantly improving detection efficiency, and can complete high-precision measurement of various 3C, semiconductor, PCB, metal workpieces, and other materials.

Contributing to the High-Quality Development of China’s Intelligent Manufacturing

As a first-tier domestic high-end industrial sensor enterprise with comprehensive R & D strength across professional fields, Hypersen has been deeply engaged in the R & D of advanced sensing technologies, continuously enriching its product line. The company has formed a mature product matrix in the fields of optical precision measurement, industrial 2D/3D inspection, and robot precision force control, and has provided high-performance sensor products and professional technical services to hundreds of industrial automation enterprises at home and abroad.

Dr. Wang Guo’an, the chairman of Hypersen, said that the company has already made substantial breakthroughs in technology, production, quality, marketing, and service. In the future, Hypersen will, as always, adhere to independent innovation and open cooperation, taking “winning the market with technology and treating customers with integrity” as the foundation, to provide customers with more high-performance, high-reliability intelligent sensor products and efficient, professional technical services, contributing to the high-quality development of China’s intelligent manufacturing.