Hypersen releases China’s first purple laser tool setter HPS-LCA100 | Enables higher-precision CNC tool measurement

- admin

- Company News

Hypersen 2024 new product release

< China’s first purple laser tool setter >

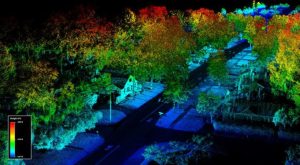

Modern manufacturing has increasingly stringent requirements for CNC machining accuracy of mechanical parts. The birth of every product is inseparable from the carving of the tool. The accuracy and stability of the tool will directly affect the processing quality. The non-contact laser tool setter can measure the tool online during the production process, eliminate workpiece dimensional deviation or quality problems caused by tool wear or damage, ensure the processing quality of the workpiece and improve production efficiency.

In view of the shortcomings of traditional mechanical tool setters such as contact wear, low accuracy, and the need for regular maintenance, Hypersen leveraged its years of accumulated experience in the mass production of high-end industrial sensors and its comprehensive R&D capabilities of light, mechanics, electricity, and computing to launch China’s first purple laser tool setter, the HPS-LCA100, which takes advantage of the shorter wavelength of the purple laser to achieve higher CNC tool measurement accuracy. Hypersen’s unique design and refined craftsmanship give HPS-LCA100 excellent performance and reliability.

_20240416200556_8872.png)

As the latest generation of high-precision laser tool setter, HPS-LCA100 uses a 405nm short-wave laser with a specially designed optical system and high-stability structure to support the measurement of various types of tools from Φ20um to Φ500mm, achieving a repeatable measurement accuracy of <0.4um. The built-in high-speed sampling circuit and algorithm support spindle tool setting speed up to 200,000rpm.

_20240417122510_3256.jpg)

HPS-LCA100 can not only measure and compensate for tool length and diameter changes caused by tool wear during machining, but can also be used to evaluate tool breakage, blade shape, tool and spindle runout, spindle temperature drift and other indicators. Compared with traditional tool setting methods, the HPS-LCA100 laser tool setter not only achieves higher measurement accuracy, but also has the advantages of high integration, non-contact, and maintenance-free, which can effectively improve the consistency of workpiece processing and reduce the maintenance cost of machine tools.

_20240416200820_2053.jpg)

HPS-LCA100 adopts a unique air seal system and check valve design to prevent external foreign matter from entering the interior of the laser tool setter, allowing it to work stably in the environment of cutting fluid and processing debris for a long time, effectively improving the service life and reliability of the laser tool setter. The highly integrated design and compact structure simplify the installation process and save valuable machine tool space. You only need to connect a cable and air pipe to get started. The three base outlet methods on the front, side and back make the installation more flexible. The built-in tool cleaning system sprays high-speed airflow to effectively remove residual cutting fluid and machining debris on the tool surface, improving the tool measurement accuracy.

_20240416200908_7560.jpg)

Laser tool setter application test

As China’s leading high-end smart sensor company, Hypersen Technology (Shenzhen) Co., Ltd. has been deeply engaged in the research and development of advanced sensing technology for many years. The core team is composed of returned PhDs from Shenzhen Peacock Talent and outstanding domestic technology R&D, production control and marketing personnel. It is a national high-tech enterprise and a Shenzhen specialized new enterprise. It has formed a mature product matrix in the fields of optical precision measurement, industrial 2D/3D detection, robot force control and other fields. Its main products include 3D flash sensors, 3D line spectrum confocal sensors, point spectrum confocal sensors, laser pairs Knife instrument, ultra-high-speed industrial camera, six-dimensional force sensor, laser needle sensor, etc., the products are widely used in industrial automation detection, 3C consumer electronics, new energy, new LED display, robots, automobiles and other fields.

Hypersen focuses on the technological innovation and exploration of high-performance industrial sensors. It has the R&D capabilities and large-scale production capabilities for the comprehensive application of optical, mechanical, electrical, and computational technologies in sensor products. It is committed to breaking through the “stuck neck” technology of China’s high-end smart sensors. Adhering to the principle of “technology wins the market and treats customers with integrity”, it will continue to provide customers with high-performance, high-reliability smart sensor products and professional technical service support, helping customers reduce costs and increase efficiency, and create more value for customers.