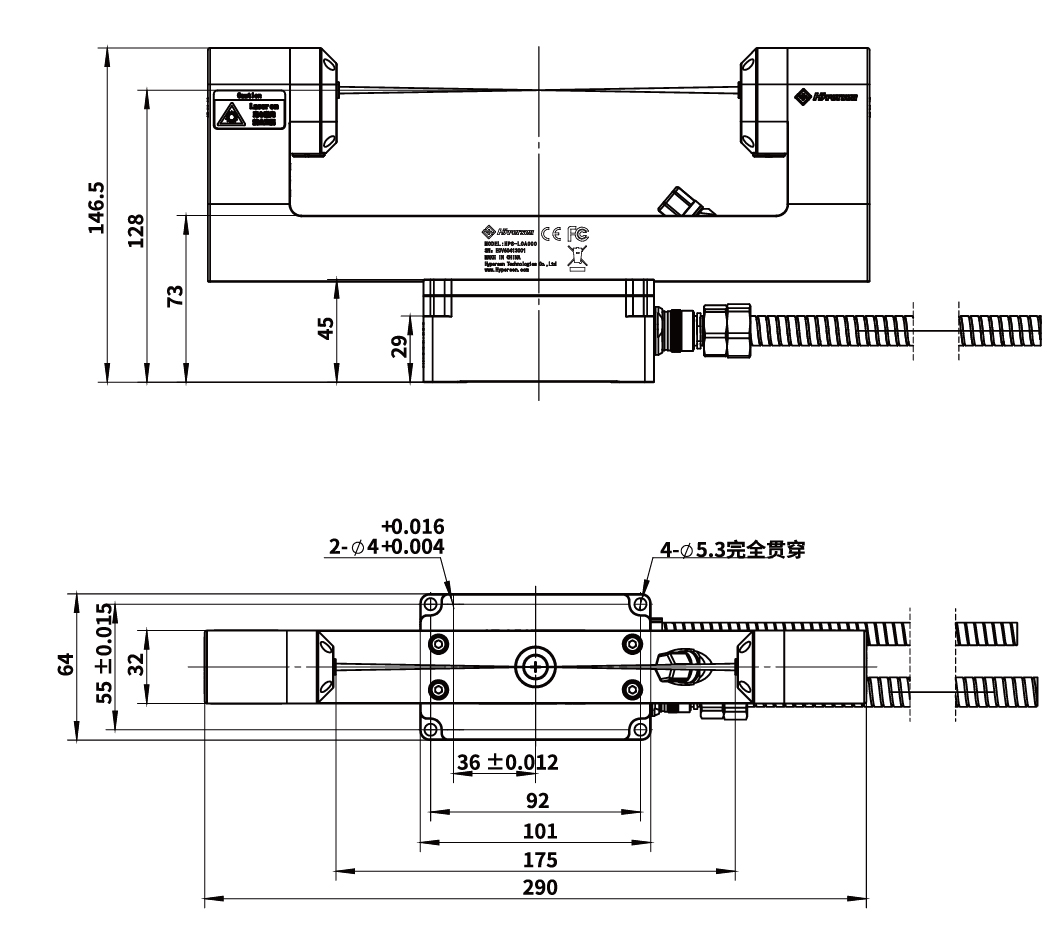

HPS-LCA100

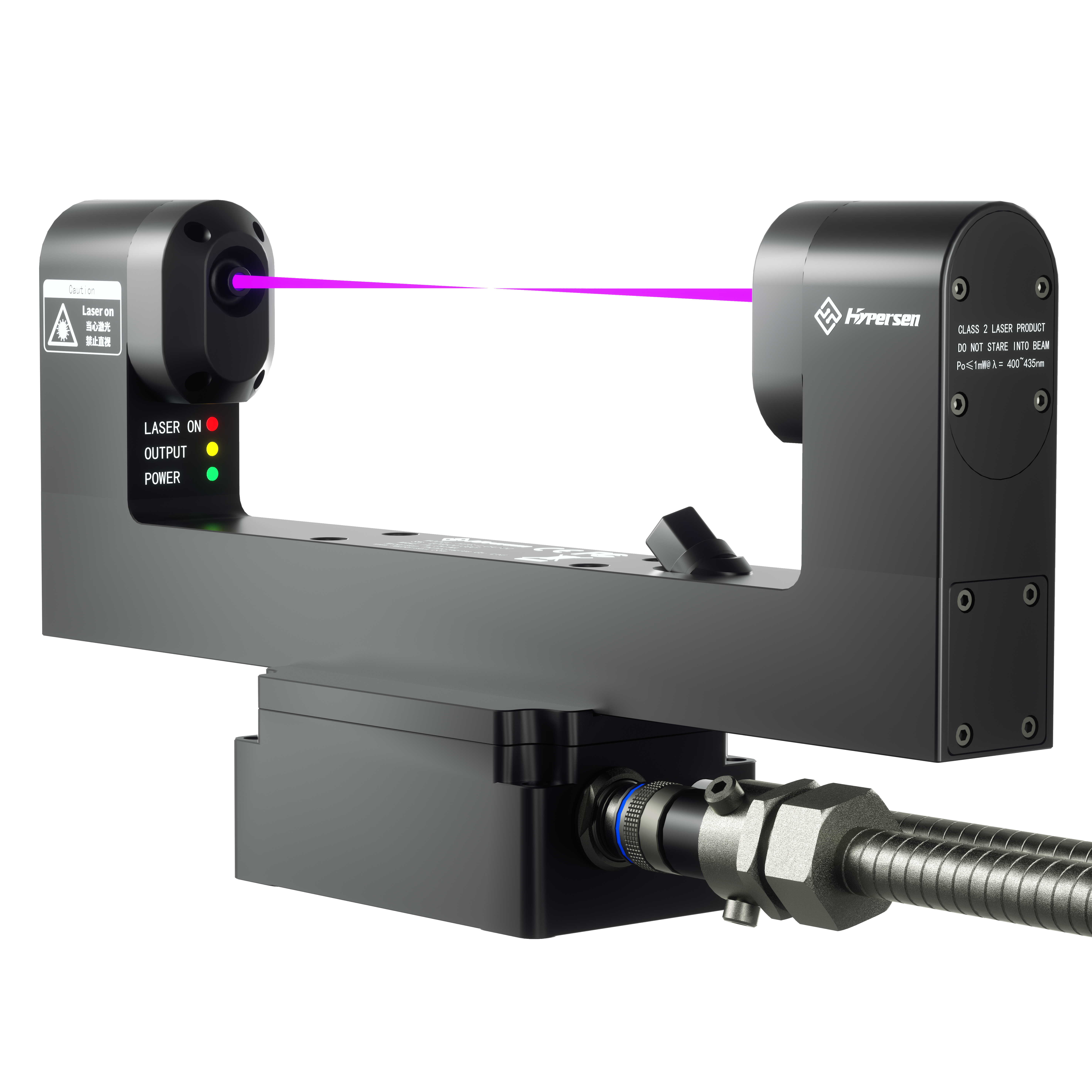

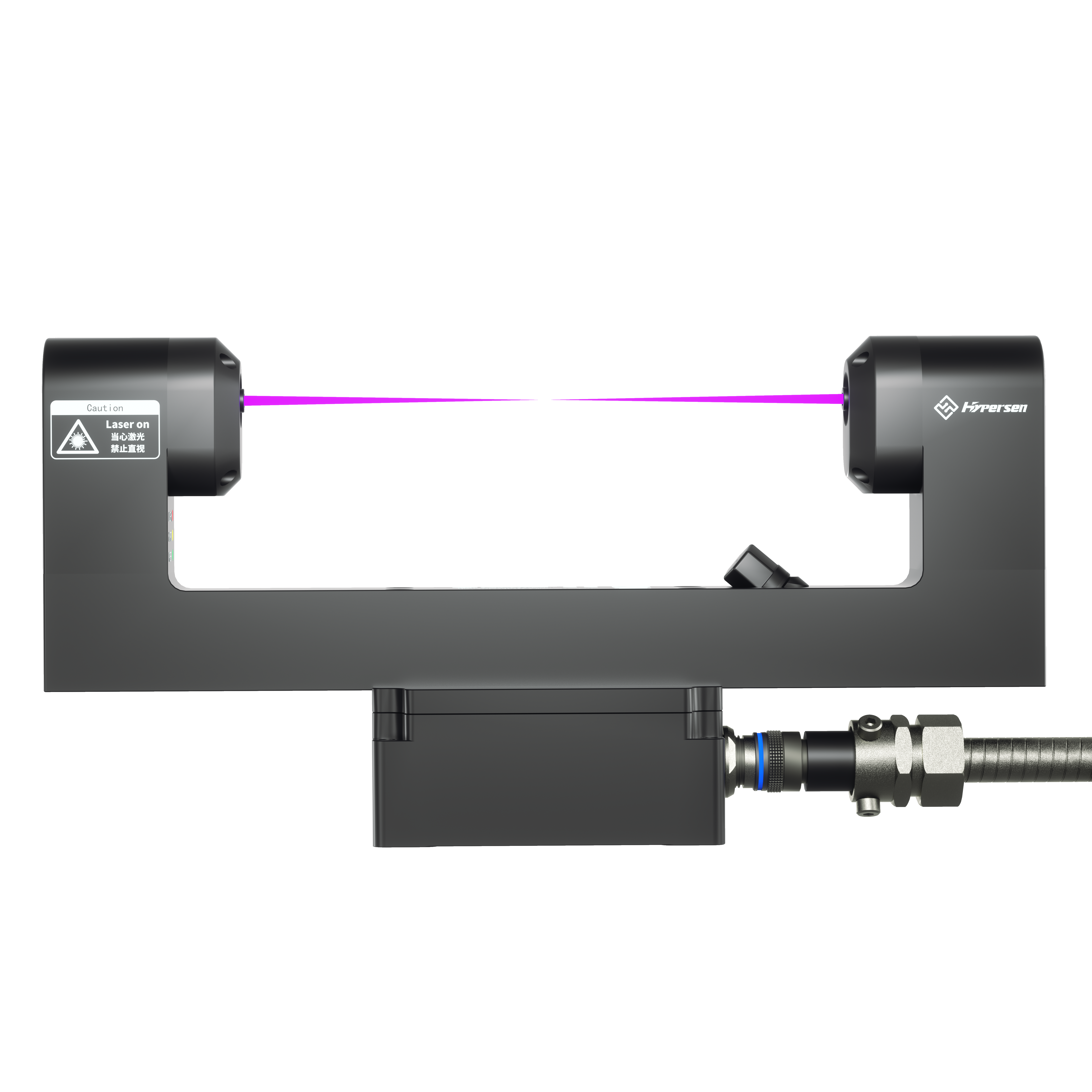

Product introduction

– High repeat accuracy and reliability

– Repeat accuracy up to 0.4μm

– Minimum measurable tool diameter: Φ20μm

– 405nm violet laser

– Integrated one – piece design

– Excellent optical system and protection design

– Built – in tool cleaning system

– Only requires connection of one cable and one air pipe, no independent pneumatic unit needed

– IP68 industrial – grade protection

– Suitable for aerospace manufacturing/precision parts machining/tool inspection/automotive parts machining

| Laser Class | Class II | Current Consumption | Violet laser: 405±5nm wavelength, power < 1mW |

| Protection Class (EN 60529) | IP68(Under the working gas supply condition) | Input/output | 3 opto – coupled isolated inputs/3 opto – coupled isolated outputs, 1 analog output, RS-232 communication interface |

| Repeatability | 0.4μm 2σ* | Min. Measurable Tool Diameter | Φ20μm* |

| Max. Tool Setting Rotation Speed (Spindle Speed) | 200,000rpm | Power Supply | DC 20V~26V |

| Weight | 1700g | Temperature | Operating ambient temperature: +5 to +45°C. Storage ambient temperature: -10 to +70°C |

| Tool Siameter Range | Vertical installation: Φ20μm – Φ500mm / Horizontal installation: Φ20μm – Φ100mm | ||

| Air Source Supply | Air pipe: Φ6.0mm×5.0m, 0.4 – 0.6MPa. Air source to meet GB/T13277 – 91 | ||

| Air quality: Grade 1. No ≥0.1μm water, oil, or dust via air source into product | |||

| If unable to meet this requirement, please select our company’s standard air source filtering device | |||

*Notes:

1.Affected by installation conditions, installation stability, distance and measurement mode.

2.All technical specifications are subject to the latest official product data manual.

3.HPS (Haibosen) reserves the right of final interpretation.